案例分析

Sub-Micron Precision for X-Ray Mirror Testing With OAV Air Bearings

Every breakthrough in precision optics begins with control - specifically, the ability to move, rotate, and measure without introducing friction or error. At the National Synchrotron Radiation Research Center (NSRRC) in Taiwan, that control became reality through the implementation of OAV Air Bearings in their advanced stitching measurement stage.

The team had to develop a multi-axis platform capable of supporting high-resolution white light interferometry, which are essential for inspecting ultra-precise X-ray mirror surfaces. These mirrors play a vital role in next-gen synchrotron radiation instruments, where nanometer-level precision is a must-have.

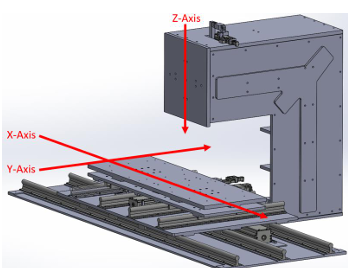

At the center of the system lies a stage design with 1200 mm of travel on the X-axis and 390 mm on the Y-axis. To enable frictionless motion over these distances, the team integrated OAV 25 mm open-block air bearings - twelve of them supporting the X-axis and eight on the Y-axis. These bearings allowed for linear positioning accuracy within ±1 micrometer over one meter, fully supporting the demands of high-resolution interferometric stitching.

Figure 1: The white light interferometer stitching measurement stage.

Rotational control was just as critical as linear precision. For the X-axis tilt, OAV 60x20 mm 3-way thrust air bushings were paired with stainless steel axles and a wedge-driven actuator to deliver controlled angular motion with accuracy measured down to just under 0.003 degrees. For the Y-axis, an OAV 150x75 mm 3-way thrust air bushing, supported by OAVF 20L40 flat air bearings, maintained precise positioning of the rotation plate, balancing both push and pull forces during motion. This setup significantly reduced friction and mechanical play, enabling the team to perform highly accurate tilt adjustments - an essential for capturing reliable surface data during mirror metrology.

Figure 2: The mechanical design of the rotation X-axis stage. The 3-way frictionless ID OAV thrust air bushings and optical encoders to measurement tilt degree in X-axis.

Together, these components created a frictionless environment where both translational and rotational movement could be executed with near-zero resistance. This allowed the Nexview NX2 interferometer to capture highly accurate image data across the full mirror surface. Thanks to the precision manufacturing of OAV’s air bearings, NSRRC’s measurement system now reaches the spatial and angular precision required to advance X-ray mirror technology - setting a new standard for optical metrology.

______________________________

Ming-Ying Hsu et al 2025 J. Phys.: Conf. Ser. 3010 012088

This material is based on work supported by the National Synchrotron Radiation Research Center (NSRRC).