Stuwkracht Air Bearing Ontwerp en installatiegids

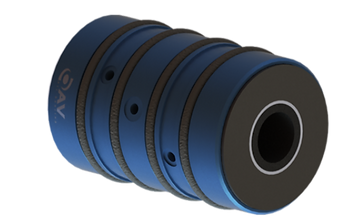

Stuwkrachtluchtbussen schuiven net als luchtbussen over de as. Het enige verschil is dat de luchtdrukbussen aan beide zijden een kraag hebben die op de as is geklemd om te voorkomen dat de luchtdrukbussen lineair bewegen. OAV-montageblokken kunnen worden gebruikt om de stuwluchtbussen vast te houden. Als een door de klant ontworpen behuizing wordt gebruikt, volg dan dezelfde richtlijnen als hieronder voor luchtbussen.

Als de as wordt rondgedraaid met een aandrijfriem, kunt u het beste twee druklagers per as gebruiken om het koppel tegen te gaan. De aandrijfriem moet altijd tussen de luchtbussen worden geplaatst. Als dit niet mogelijk is, houd de riem dan zo dicht mogelijk bij de eerste persluchtbus. Statistische vergelijkingen kunnen worden gebruikt om de belastingsvereiste op elke drukbus te bepalen.

De onderstaande diagrammen tonen twee algemene voorbeelden waarbij F1 de spanning van de aandrijfriem is, F2 & F3 de krachten zijn die op de bussen werken, en d1 en d2 de afstanden zijn vanaf het midden van de riem en de luchtbussen.

.jpg)

Ontwerp- en installatiehandleidingen

Figuur 1. De aandrijfriem tussen beide stuwluchtbussen. Dit wordt aanbevolen, omdat de spanning op de riem wordt verdeeld over beide luchtdrukbussen, zoals weergegeven in de onderstaande vergelijkingen.

F3 = F1* d1/(d1+d2)

F2 = F1* d2/(d1+d2)

Stel: d1 = d2:

F2 = F3 = .5*F1

Figuur 2. De aandrijfriem buiten de twee stuwluchtbussen. Deze configuratie werkt het beste met een kleine afstand d1 en lange afstand d2. De bijbehorende belastingsvergelijkingen staan hieronder.

F2=F1*(d1/d2+ 1)

F3 = F1* d1/d2

Beschouw de opening tussen de bus en de gezichtskraag als verwaarloosbaar. De gezichtskraag wordt tegen het wrijvingsloze oppervlak van de drukbus geplaatst. Zodra de luchttoevoer is ingeschakeld, ontstaat er een kleine opening. Daarom kan de totale lengte van het drukbussysteem worden bepaald met de volgende formule:

lengte van de linker kraag + lengte van de luchtbus + lengte van de rechter kraag

Housing Installation

The three methods of housing installation are epoxy, O-rings, or a light-press fit. OAV mounting blocks allow for the epoxy

and O-ring methods of installation. In most cases it is recommended to design using O-rings, because O-rings have self-

aligning features that can be readjusted.

Designing With Epoxy:

If epoxy is used, make sure that the epoxy grooves on the bushings can be accessed with a syringe.

Designing With O-rings:

If O-rings are used, make sure to use the appropriate bore size and tolerance. OAV can also provide this information.

Designing With The Light-Press Fit Method:

If a light-press fit method is used, make sure to use the recommended bore size and tolerances. OAV can also provide this

information.

Other Considerations:

Air bushings rely on the straightness of the shaft. Design so that the deflection/displacement of the shaft is minimal.

Installing bushings with O-rings:

1) First do a quick visual inspection to ensure that there are no sharp edges in the bore of the mounting block. The o-rings

provide a very tight fit and if they get damaged, they will not work properly.

2) Lubricate the O-rings and surfaces with alcohol.

3) Press-fit the bushing inside the mounting block.

4) Insert the shaft and apply the air pressure. 30 PSI is enough to test the bushing without any load being applied.

5) Use proper alignment. If two shafts are used side-by-side, it is best to use gages to assure that the shafts are at an equal

distance from both ends. Parallelism is crucial for optimal performance of the air bushings.

Installing Bushings With Epoxy:

1) Clean the surfaces with alcohol.

2) Slide the air bushing into the mounting block, and the shaft into the bushing.

3) Align the shaft(s) with the best parallelism possible. If two shafts are used side-by-side, it is best to use gages to ensure

that the shafts are at equal distance at both ends. Parallelism is crucial for the performance of the air bushings.

4) Turn the air supply on at 30 PSI and do not apply any load to the bushing.

5) Use a syringe to apply the epoxy through the syringe holes on the mounting block until the epoxy fills the epoxy grooves

on the bushing. Make sure that the air port on the bushing lines up with the air port on the mounting block.

6) Keep the air supply on at 30 PSI until the epoxy cures.

7) Epoxy installation should only be performed after shaft alignment is confirmed

Installing Bushings With The Light-Press Fit Method:

1) Clean the surfaces with alcohol.

2) Light-press fit the air bushing into the mounting block, and the shaft into the bushing.

3) Align the shaft(s) with the best parallelism possible. If two shafts are used side-by-side, it is best to use gages to ensure

that the shafts are at equal distance at both ends. Parallelism is crucial for the performance of the air bushings.

4) Make sure that the air port on the bushing lines up with the clearance hole on the mounting block.

5) Install the air fitting directly into the air bushings as shown above.

Shaft and Face Collar Installation

1) Clean shaft surface with alcohol and a lint free cloth. Check for any surface imperfections. Shaft surface finish should

be 16 RMS or better.

2) Insert shaft in bushing with operating air on.

3) Clean face collar working surfaces with alcohol and a lint free cloth. Check for any surface imperfections.

4) Install first face collar in position on the shaft and tighten firmly.

5) Install second face collar on the shaft, press against the graphite thrust face with the operating air on, and tighten firmly. Gap will be set automatically by running air.

Mounting Alignment:

Mounting blocks should be installed in their permanent position after shaft install or secured loosely during shaft

installation. This will allow alignment adjustment between the block, O-ring compression, and running air. Mounting

blocks should be secured firmly after shaft installation and alignment is confirmed.

Temperature Controlled Thrust Air Bearings:

The temperature control bearings have three ports – the center port for bearing operating air, and ports on either side the

inlet and “exhaust” of temperature control fluid. Operating air and temperature control fluid do not interact withing the

bearing. Any fluid can be used, but air is most common. Operating air inlet and circulating fluid inlet should be

independent feeds to control pressure, flow, and temperature as needed.

Extreme Temperature Conditions

At temperatures below freezing, water will be drawn out of the air and can crystallize internally, impeding flow and

degrading performance of the bearing. This crystallization can occur in both operating air and temp control fluid when air is

used. Severity and likelihood of occurrence are dependent on severity of temperature, operating pressures, flows, ambient

humidity. This can be counter acted by using:

1) An in-line air heater

2) Compressed air dehumidifier

3) Pure compressed gas, such as helium or nitrogen (where practical), due to the homogenous state lacking water

contamination.

At high temperatures, maximum exposure temperature is dependent on application and precision needs, and control may be

aided with refrigeration of air and circulating fluid.